What are Critical Minerals

Mineral sands are ore deposits that contain ‘heavy minerals’ such as Zircon, Rutile, Leucoxene and Ilmenite, which are commonly found together as coarse and fine grain of sand.

Vital and valuable natural resources, mineral sands supply raw titanium materials for the manufacturing of titanium oxide pigments and titanium metal alloys, along with highly valuable zircon, these products have many uses in the production of everyday life materials including toothpaste, ceramic tiles, bathroom ware, crockery and specialty ceramics.

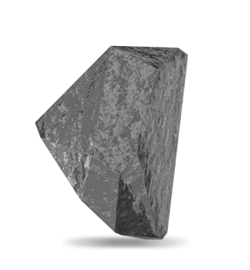

Zircon

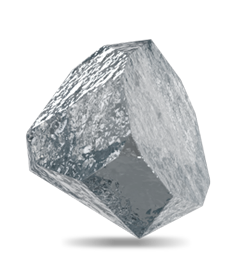

Rutile

Leucoxene

Ilmenite

Mineral sand deposits that are economically viable to mine and process contain a concentrated amount of ‘heavy minerals’ within the lighter predominantly quartz sands grains.

Originally formed as crystals in igneous rocks, such as granite, basalt and some metamorphic rocks, these minerals were eroded by wind, rain, frost, and rivers over millions of years. The resulting grains were washed down to the sea to become part of the coastal sands of ancient beaches.

In areas where high energy oceans occurred the lighter mineral sand grains, such as quartz sands, were separated, leaving concentrations of heavier mineral sands on beachlines. As the world’s ocean levels rose and subsided, the deposits were buried, and therefore they are often found more than 100 kilometres from modern day beaches.

The Murray Basin, which covers parts of Victoria, New South Wales, and South Australia, is an ideal location for this concentration process. Home to an ancient inland sea during the Cenozoic Era (up to 66 million years ago), large deposits of heavy mineral sands formed when heavy minerals entered the Murray Basin through river systems and the high energy Southern Ocean provided the concentration process.

How are mineral sands mined?

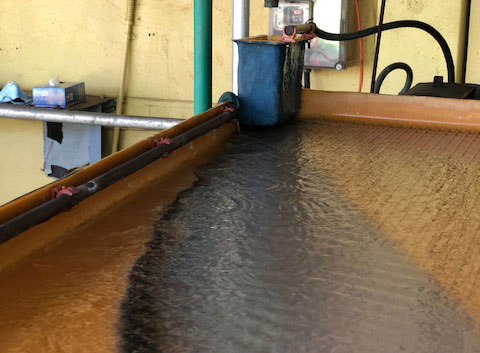

RZ Resources will employ a wet dredge mining techniques due to the abundance of highly saline water in the area. A dredge floating in a pond extracts the ore and pumps it to the adjacent floating concentrator, whereas dry mining uses traditional earthmoving equipment such as dozers and trucks supplying a static processing plant.

The floating dredge and concentrator mining and processing minimise the mining disturbance and allows continuous rehabilitation of the previous landform behind the pond.

For more information, please read the Mineral Council of Australia fact sheet found here.